Major Sections:

GKMOSS Boilers

Professional Industrial support for wood, gas, and oil boilers. Please take a moment to browse our brochure or contact us for more info!.

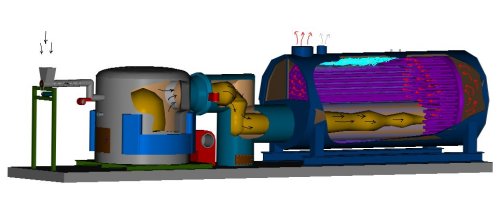

Fire tube

Firetube Boiler

Moss firetube scotch marine boilers are 2 or 3 pass dry or wet back units ranging in size from 150 - 1000 HP with design pressures from 15 - 350 PSIG. This boiler design can be supplied with a Moss gasifier with thermal reactor combustion system. The firetube design allows for quicker installation time at the jobsite. The combustor/gasifier system is installed with 9" of castable refractory or firebrick and 2" of 1900° F. insulating block. The system is provided with underfire, thermal reactor and induced draft fans. This system provides the best performance while providing very low emissions. Ash can be removed from the gasifier chamber either automatically or manually. Ash will drop out in areas where the gases change direction. All boilers are provided with skids and are designed to be installed on a foundation pad, concrete piers or structural steel. Our large firetube boiler furnaces provides the required combustion volumes for complete burnout and cooling of gases before the entrance into the second pass tubes. The large steam storage and disengaging area in the firetube boiler helps prevent drops in steam pressure and water carryover to the process. Large turnaround space at the end of the first pass helps prevent tube damage to rolled or welded boiler tubes. An automatic sootblower system is available as optional equipment and is strongly recommended for extended runtime between boiler tube cleanouts.